-40%

¡100% CHARITY! Dedicated Concave Lapping Plates f/ Shave Ready Straight Razors

$ 19

- Description

- Size Guide

Description

¡100% Charity 5-Day Auction, YOU GET BOTH PLATES!I'm even picking up shipping, and this costs > to mail to MST/PST!

You'll have precisely

five

chances to buy this pair of extremely rare metal objects, be sure you don't have FOMO forever...it benefits the kids! I predict the order of low payer = 4 2 3 1 5, but that's what's fun about auctions or losing money at a video poker machine, you get to see what happens

(what happens is you lose)

.

__________________________________________________________________________

Fellow human, if European razors cease to be produced, this author would likely lose their home - so you can be sure the goal at all times at this eBay vendor's pages is to keep this great tradition alive. Down with beards! Screw your dumb wanker beards! You all look stupid!

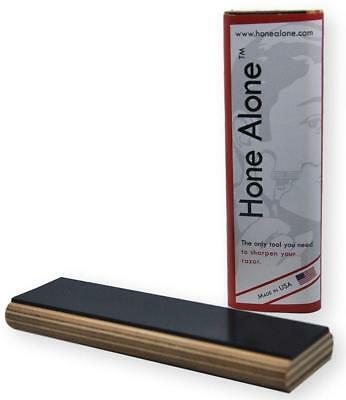

This is a pair of sandpaper holders, made of 6061 t6 aluminum, intended to help shape any razor hone

(you buy your hone separately, and if you choose an unmounted Naniwa Super Stone you will think you've died and gone to heaven)

. You’re just buying shapes, really; if such rigid shapes could be found easily in nature

(and we could take them toward our sinks for their easy use)

, the plates would offer no function – but you’ll find in seeking that some shapes are indeed a tough source.

Forming your hones with these plates produces concave cutting edges

(bevel)

upon your razor, which is how Western Hemisphere hollow ground straight razors have been produced since the later 1800s.

Unfortunately until now, there was never an easy way for end users to maintain a wheel-shaped hone. By contrast, it’s always been easy for home users to maintain a flat stone

(in spite of how common it is to find a dished

{= concave}

old hone)

. This is the reason one so often reads that flat hones are ideal for straight razor honing. But flat (V-shaped) cutting edges are not ideal for straight razor shaving, and never were.

If the goal of honing a razor is to produce an edge with the maximum possible comfort available from that particular razor, the geometric position which accomplishes this is with the bevel itself also made concave

(by using a wheel)

, and as thin as possible until it would crumble from becoming too thin for its assigned task

(we do not approach that risk here with this tool on any properly-hardened Western razor, btw)

.

- Concave

abrasive fields produce

convex

, durable cutting edges

(inappropriate for shaving)

. You’ll find them upon axes and other tools designed for rough jobs.

- Flat

abrasive fields produce V-shaped

flat

(= isosceles triangle)

cutting edges; less durable than convex edges, more durable than concave edges, they’re appropriate for shaving (but not ideal).

- Convex

abrasive fields produce

concave

cutting edges; more fragile than flat V-shaped or convex edges, materially thinner, with a reduced edge radius, and a reduced effective cutting angle versus any convex or V-shaped cutting edge produced upon the same tool.

Factory-honed edges are ~rough

(costly labor time!)

and improved by further honing post-factory upon flat abrasives. However, rough concave factory edge still possess those geometric advantages, which once removed via honing upon flat hones

(= as all common N.American ‘honemeisters’, though Honemeister "

The Sharpening Guy"

bought plate)

are partially lost forever. The maximum distance from the cutting edge to the spine for any given razor is where it is most potentially flexible, and flexibility is a crucial facet of any modern forged razor. When anyone touches a factory edge with any flat hone, they can improve the edge refinement and polish of its sides, but only at the expense of edge thickness, radius, and cutting angle, each altered slightly to the opposite of what you should seek in a hollow ground razor if you place its thinness/flexibility as more important than its appearance of wear or upon the remaining thickness of your whetstones.

We do not have wheel-hones available to us today, for they haven’t been commercially produced in fineness appropriate for straight razor finishing for over one hundred years. This lapping plate tool, however, does allow you to emulate a modest

(= large diameter)

wheel, by reshaping your rectangular hone; you end up carving the wheel shape out from within your

(former)

rectangle.

This pair of plates have the same primary diameter with one a simple cylinder and the other an elliptically-shaped honing surface. I am happy to say that in production, while standards were high, the cylinder erred to the short side of diameter, which is a great 'mistake'. Using an ellipse requires more practice to become proficient than using a flat plane. But typically, a master grinder finishes with elliptically-shaped hone, which are much more challenging to master than honing upon cylinder-shaped hones. So, we also give you a cylindrical shaping plate

(but we also can’t imagine anyone using each and choosing only to have the cylinder…a cylinder has place, & winning feedback-joy contests ain’t it)

.

Use your ellipse plate normally

(= shape your hone’s length toward the plate’s 11″ axis)

, keep your spine 90° to the length of your stone during honing, and your hone moves 0.015mm into the hollow grind of the razor, then returns toward that same shared triangle tip but from a lower pitch vs any flat thing. That lower approach back to the edge starting from within the razor is what causes the extra comfort you feel on your face, and why you see your bevel get wider. It is a wider, lower angled, and physically thinner bevel than before. This is mathematics.

If your hones are deep and not too lengthy, try aligning your hone’s length to the elliptical plate the “wrong” way

(= stone’s length smartly facing 9″ axis while lapping)

and it will consume ~5.30mm off a perfectly-flat 3×8″, ~2.93mm off a 2×6″, and give a more aggressively-concave and significantly superior shaving edge. Upon a normal 6/8″ razor, your finished hones would then work 0.041mm into the hollow grinds of the razors, an undeniably-large distance at these scales. The expenses incurred to achieve this incredible shaving result are the whetstone depth needed to form such small wheels

(you’ll be carving away much more of your rectangular hone from its corners)

and the altered appearance of the razor’s bevels and spines. Typically, given that the smaller the wheel the more skill required of the grinder to finish upon it, such a small diameter would not be used throughout the honing, and instead would act to thin out a bevel’s form and pair with a larger diameter hone(s) to ease the challenge of meeting the edge’s true apex. If you have tremendous hand skill you can successfully set and refine your edge off of this 6.5'x25' geometry, however, so don't sell yourself short. "Low man wins" meaning lowest diameter is best, but we all cheat by using larger diameters later or for example from the flat geometry razor realm you knew before, adding a layer of tape or using a pasted strop at the end are means to compel action to the edge of the edge...same thing happening if you do early honing with 6.5'x25' and finish on 25'x6.5', just that all of it is occurring in an area geometrically impossible with flat things.

If you require proof of this method being preferred exclusively for its honing results [and are blessed with a dutiful attention span and some ability to translate German], the 175-year-old textbook

Polytechnische Mittheilungen Volume 3

(c. 1846)

pp 28-43 will teach you more than you ever knew before about straight razor sharpening. Today’s straight razor enthusiast should understand that while advances in abrasives have certainly occurred since the dearth of the straight razor as common man’s tool, much information from that time was also lost to history or simply never arrived to the English-based PDFs Google Book world and is “buried” in old fashioned paper in some libraries on Earth. The published information is present, somewhere, in German and other languages, but only if you know what to search in non-English languages and in physical locations of physical books.

Unfortunately and as completely ridiculous as this sentence should hopefully appear to you if you’re just entering this theoretical discussion, there’s a cabal of straight-razor-centric-forum-enthusiasts who are as a lot much more concerned about appearing not to know about a nineteenth century honing innovation

(and doing everything in their power to squelch the English dissemination of this knowledge)

than they are about getting the best shaves for themselves. See for yourself on nearly any US-based forum!

What you will not find, in time, is anyone selling these concaved plates secondhand unless they’re taking some profit from the low price they paid St. Jude's here and flipped it later

(like a boss)

. Never say never, but the odds another 9x11-inch straight-razor-specific lapping field is ever offered commercially is almost impossible, in this professional opinion; our competition will look at how fairly we’ve been treated for reintroducing this old sharpening technology, and realize that whatever people state as fact upon shaving forums, real or otherwise, is today’s gospel! But you, the intelligent caring straight razor user with a soft spot for sick children, can vote with your dollars in the opposite direction.